Kettles

Kettle Elements

Manley used three different types of heating elements for their

kettles--internal, ring, and Cartridge.

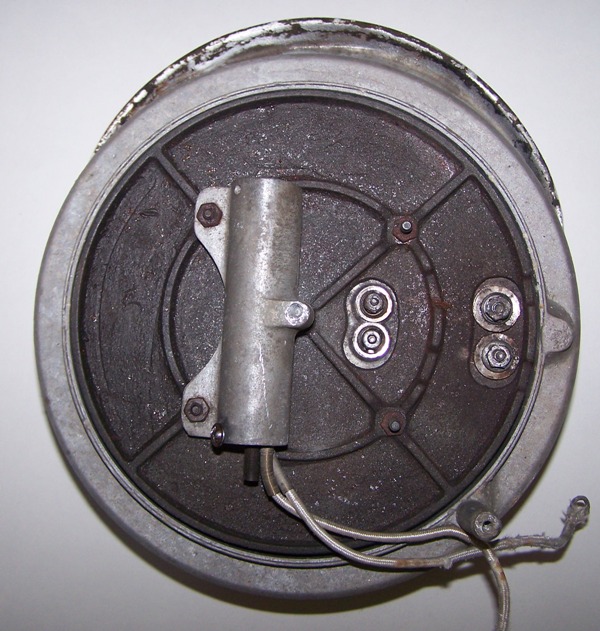

The Manley M-line generally used an internal element. Here is the

bottom of the kettle from an M-47:

You will note that this kettle has two sets of internal heating elements.

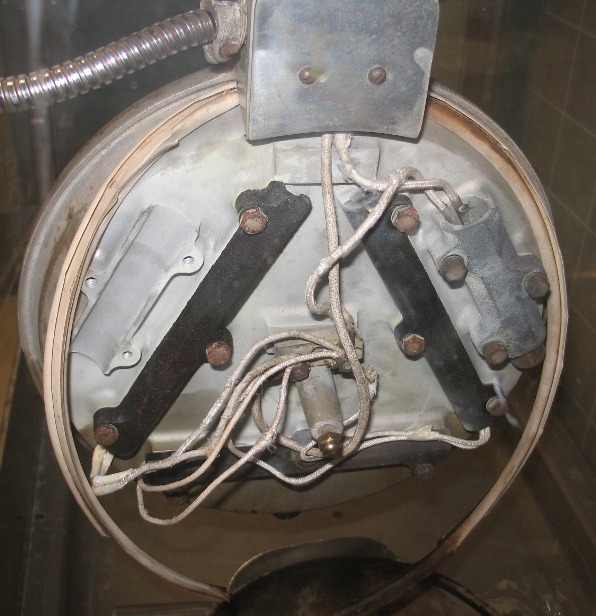

The Premier models tended to use ring heaters. Ring heaters are

bolted onto the kettle, and are therefore, a separate piece. In some

cases the two ring heaters are combined as one piece or in other cases they

are two separate ring heaters. The following photo is from a Premier

model:

Note that the wires have been removed from this kettle. I removed

the wires as part of the restoration process as the insulation on the high

temperature wire failed, shorting out the kettle. The ring heaters

were still good.

Typically, the Aristocrat kettle used three sets of internal elements.

Two of the sets of elements are wired together allowing separate control of

two different sets elements. Having one set on was low heat, the other

set on is medium heat, and both sets on is high heat. This provided

more control over the temperature of the kettle. Even though three

wires (black, red, and white) go to the kettle, it is only a 110 volt

kettle. Here is the bottom of a Manley Aristocrat kettle:

The third style of element is the cartridge. Again with this style

the heating element is separate from the kettle itself. Below is a

photo of the kettle bottom from a Model 128 Vista Pop:

Note in this case that three separate cartridge elements are used on the

Manley kettle.

Thermostats

Manley used two different types of thermostats on their kettles.

Typically, the M-line used a 3/4" snap disk thermostat, while the Premier,

Aristocrat, and Vista Pop used cartridge style thermostats.

Specifically, the thermostats served as a high limit switch. When the

temperature of the kettle became too hot, the thermostat would open to

"turn-off" the elements until the kettle cooled to an acceptable

temperature. Therefore, these thermostats would be open on rise

thermostats.

You want the temperature of your kettle to be around 450°

F for your corn to pop correctly. However, you do not want your kettle

to reach the flash point of coconut oil (or other oils) used for popping the

corn. The flash point of coconut oil is around 550° F.

Here is a thermostat from an M-47 kettle:

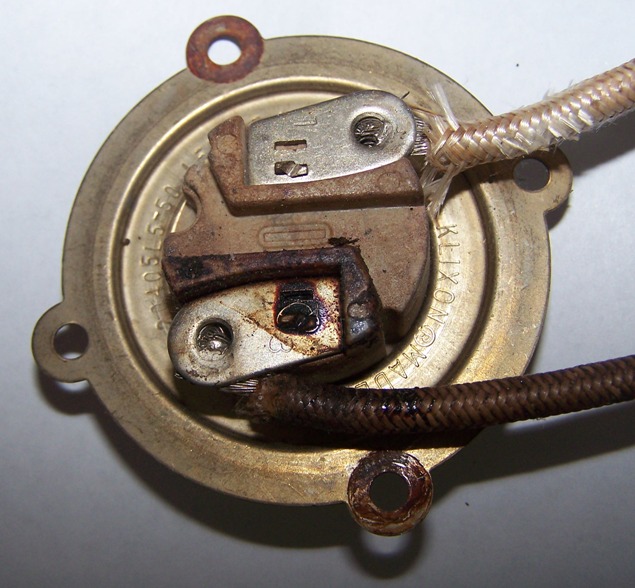

Here is a cartridge thermostat from a Premier model:

There is a set screw on the end that can adjust the temperature of the

cartridge thermostat.

Testing Kettle

The good news is that kettles made with internal elements are almost

indestructible. On the other hand kettles made with ring or cartridge

heater are not as indestructible as the internal elements kettles, but

replacement parts can be found.

In many cases the last thing to go is the heating element itself.

Your first step should be to determine that power is reaching the kettle.

When you are dealing with 50-60 year old wire, it is likely that the

insulation has become brittle and part of the insulation may be missing.

Obviously this leads to shorts. Not to mention that wire insulation

from this period tends to get attacked by rodents. They tend to find

this wire insulation tasty. :)

The next step is to perform a continuity test on the total kettle.

If you are not familiar with a continuity test,

try this link. This can be done with the kettle shroud in place

and conducting the test across the thermostat and kettle elements. If

you have continuity, the kettle is probably fine.

If the continuity test fails, you need to test the thermostat and

kettle elements separately. To do this you must remove the shroud from

the kettle to get to the kettle wiring. The kettle elements are wired

in parallel, with the thermostat in series with the elements. You

should perform a continuity test on both the thermostat and the kettle

elements. You will need to remove the lead wire from the thermostat

that is attached to the kettle elements. With this lead wire removed

you can now perform a continuity test on the thermostat and then on the

kettle elements. If you have continuity on the both parts, then you

kettle should be good. If either fails then that part is defective.

Remember the thermostat is an open on rise (open on rise in temperature)

style and should have continuity at room temperature.

Common Problem

The more common problems are not the elements, but getting electrical

current to the kettle. The wiring has already been mentioned.

But another common problem is the switches themselves. It is

common to have a switch that has failed.

Obviously this could prevent power from reaching the kettle.

Another common problem, especially on the Premier models is that the high

temperature wire has failed within the kettle. I have two premier

kettles and in both cases the elements were good, but the insulation on the

high temperature wire had failed and shorted the kettle. Replacement

of the high temperature wire in the kettle (under the shroud) should put the

kettle back in operation.

Replacement Parts

If the internal elements on the kettle are burned out, you will need a

replacement kettle. It will have to be a salvaged kettles as replacement

kettles are not available. If you have ring heaters or cartridge heaters,

you can find replacement pats.

For thermostats, the 3/4" high temperature snap disc thermostats are not

made any more (if someone finds a source please let me know). However,

1/2" high temperature snap disc thermostats are made today. I think it

would be possible to make a mounting bracket for one of these. The

cartridge thermostats are still made.

Cautions

Remember you are dealing with electrical wiring and using it to heat the

kettle to around 450 degrees. Please exercise appropriate precautions.